Product Description

Double girder electric hoist bridge crane has such features as tight dimensions, low building headroom, light dead weight and light wheel load. They are applicable to the transfer, assembly, check and repair as well as load and unload at mechanic processing workshop, subsidiary workshop of metallurgical mills, warehouse, goods yard and power station. They can also be used instead of common double girder overhead crane at production workshop in light textiles or food industry. It has two kinds of classification, that is, light and medium. The working ambient temperature is generally-25℃to 40℃. It is forbidden to work in environment with combustible, explosive or corrosive media.

- Double girder electric hoist overhead crane are ideally suited to low buildings and heavy fabrication, where a high hook lift height is required.

- The top running configuration is best used in cases where the end user has issues with headroom.The most space efficient configuration is the double girder, top running crane system.

- Two girders are simply stronger than one, making HY double girder traveling cranes the ideal solution for the area coverage handling of heavy loads up to 300/40t.

- HY double girder cranes feature welded box beams. All the sections girders are computer-optimized for high performance and low weight, benefits that pay in terms of strength and cost efficiency.

- Lifting capacity: 0.25-20ton

- Span length: 7.5-32mtrs

- Lifting height: 6-30mtrs

- Working duty: M3-M5

- Power: AC 3Ph 380V 50Hz or according to client's requirement

- Control mode: Cabin control/remote control/control panel with pendant line

Parameters

| Mechanism | Item | Unit | Result | |

| Item | ||||

| Lifting capacity | ton | 5-32 | ||

| Lifting height | m | 6-30 | ||

| Span | m | 7.5-25.5 | ||

| Working environment temperature | °C | -25~40 | ||

| Speed | Main Hook | m/min | 3(0.3/3)-8(0.8/8) | |

| Auxiliary Hook | 7(0.7/7)-8(0.8/8) | |||

| Crab | 20 | |||

| Trolley | Ground | 20 30 | ||

| Room | 30 40 45 | |||

| Working system | A3-A5 | |||

| Power source | three-Phase A C 50HZ 380V | |||

Benefits

Best Quality

Fast Delivery

Global Service

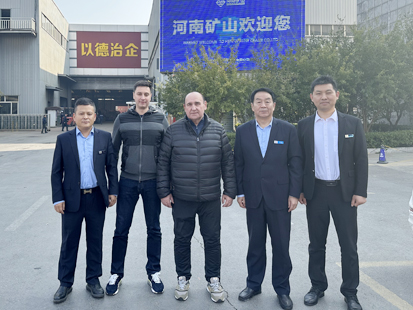

Customer Site

Packing and Shipping

We strictly manage packaging specifications and transportation requirements,Wooden pallets with plastic filmor according to your request.

FAQ

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.